Previous

Next

Rapid Tooling

We offer rapid prototyping and low-volume injection molding. Rapid injection molding is like end-use prototype manufacturing.

Overmoulding

Overmolding is a way of combining two or more components together using injection molding. It is the best way to make multi-color and multi-layer products.

Insert Moulding

Insert molding is an injection molding process that encapsulates components in a plastic part. It is used for designs with threads and holes.

Our Services

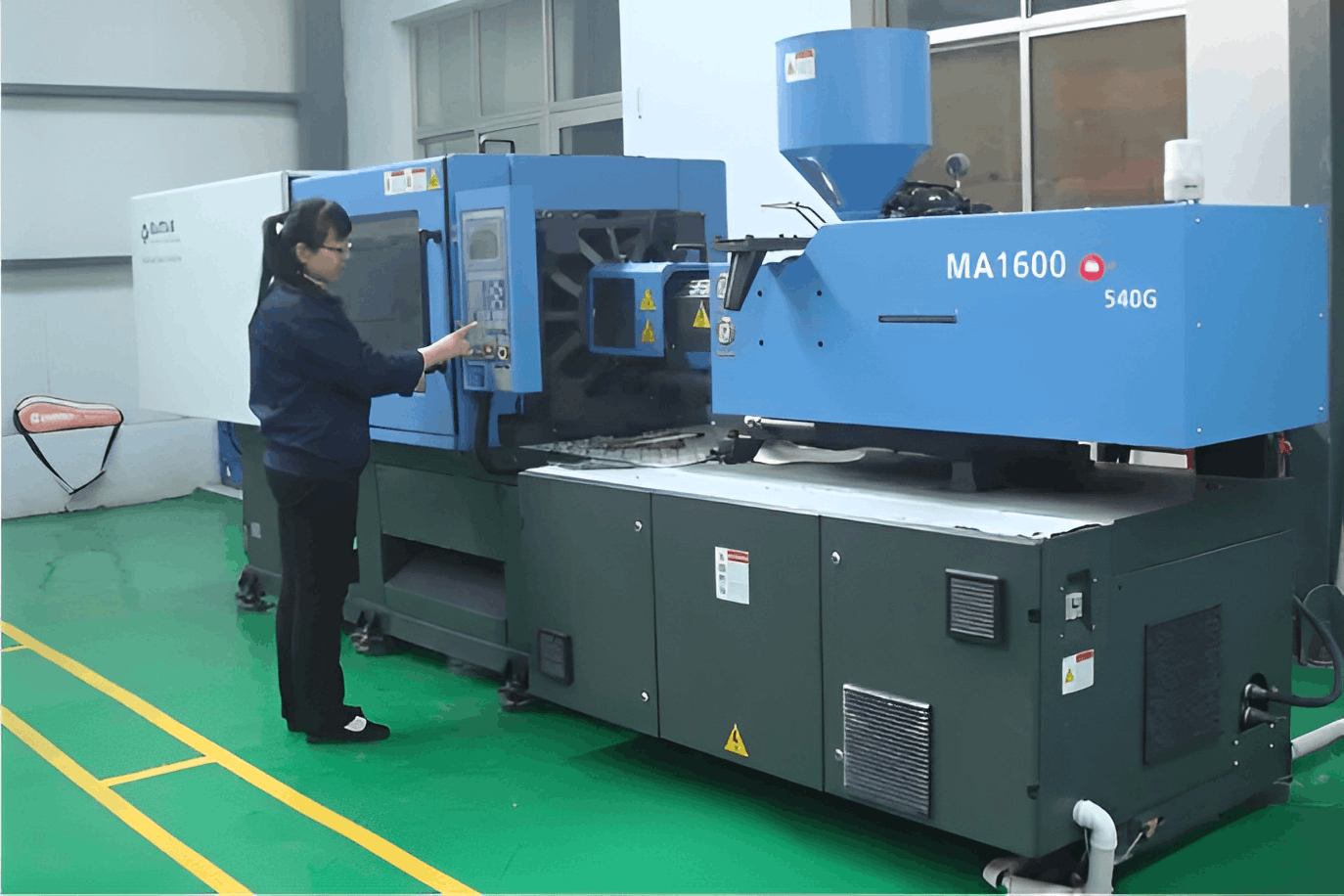

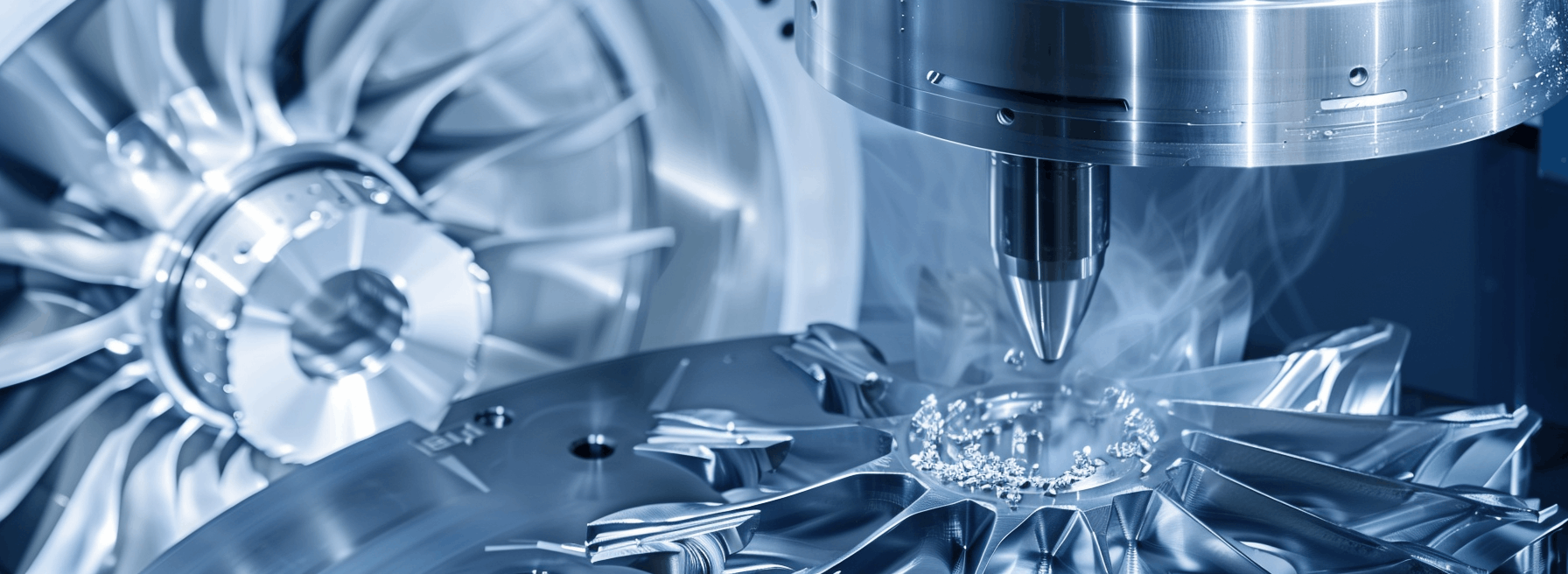

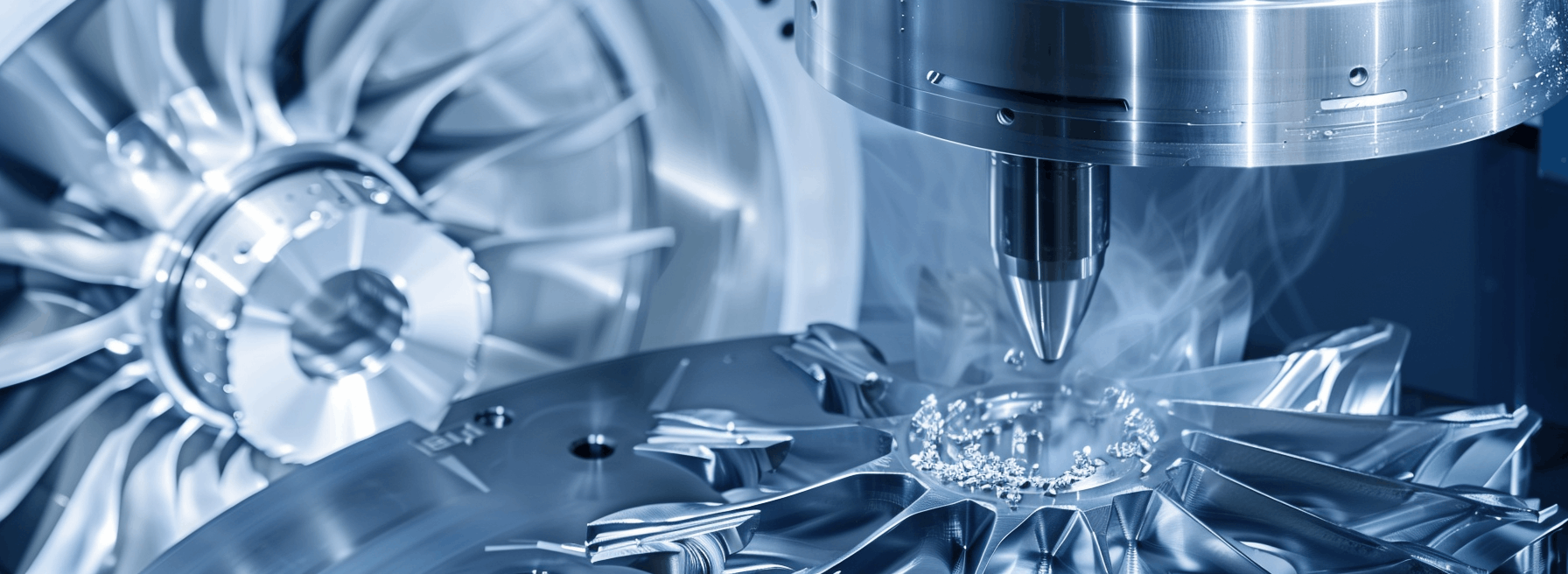

Our Custom Plastic Injection Moulding Services

Injection molding is our top choice for making small plastic parts. It’s precise, repeatable, and cost-effective. Our plastic injection molding services have made a variety of parts, from small medical parts to large automotive and aerospace parts.

Need help?

Call us for more information or business inquiry.

+86 18923709879

Wind Farms in Wales

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Wind energy at Monaco

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Jakarta Airport International

Faucibus phasellus placerat aptent semper leo sagittis felis consectetur malesuada taciti per senectus netus auctor

Custom Injection Molding Parts

Previous image

Next image

Start production today.

Make on-demand manufacturing easier and faster.

LRD Prototyping Capabilities

LRD Prototyping | Description |

| Machine size | 50 – 3000 ton |

Mould tool material | aluminium and steel (various grades) |

Shot life | 500 to 1M+ shots (MOQ of 1) |

Mould type | single cavity, multi cavity and family mould |

Lead time | T1 samples as fast as 2 weeks |

Injection Moulding Materials

| Materials | Description | Appearance |

| HDPE | HDPE is a low-cost thermoplastic with good impact and chemical resistance. It is used in many applications, including bottles, cutting boards, and piping. | Black, white |

| PA | PA plastic injection molding material is versatile, durable, and flexible. It can be used in many applications. Due to its high melting point, it is an excellent alternative to metal components in high-temperature environments. | Black, White, Beige |

| ABS | ABS is a popular material for injection molding. It is rigid, versatile, and resistant to chemicals and weather. It is often paired with a chrome finish to make high-quality automotive accessories. Material Reference ABS, ABS+GF, ABS+UV resistant, food grade ABS, PC+ABS | White, Black, Cream, Milky |

| PBT | PBT is strong, rigid, and resistant to thermal deformation. It is used to make sockets, switches, and handles. Material Reference PBT, PBT+GF | White to Bright Color |

| PC | PC is resistant to impact, wear, and functional testing. It is used in the medical, automotive, and telecommunications industries. Material Reference: PC, PC+GF, PC+ABS | Black, Translucent (or polished transparent) |

| PMMA | Acrylic or PMMA injection molding makes high-quality clear and transparent parts and prototypes. SPI grade A mold finish makes parts clear. | Translucent, Black |

| PP | Polypropylene (PP) is a thermoplastic material used in injection molding. It is durable, resistant to many factors, and often considered a safe option. Material Reference PP, PP+GF, food grade PP | Many colors |

| PPS | PPS is a great choice for thin-walled plastic injection moldings. It is a rigid polymer with excellent high-temperature and chemical resistance and good electrical insulation. PPS is commonly used in medical devices and surgical instruments. | Opaque white to light tan |

Injection Molding Tolerances

| Grade Size | 0.5-3mm | 3-6mm | 6-30mm | 30-120mm | 120-400mm | 400-1000mm | 1000-2000mm | 2000-4000mm |

| Fine | 0.05 | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 0.5 | / |

| Medium | 0.1 | 0.1 | 0.2 | 0.3 | 0.5 | 0.8 | 1.2 | 2 |

Plastic Injection Molding Surface Finishing

| Applicable Materials | Colour | Description | |

| SPI Mould Finishes | All | / | SPI A1-3, B1-3, C1-3, D1-D3. |

| Painting | All | Black, Pantone/RAL colours | Painting adds color to a part. It makes a part look better. |

| Chrome Plating | All | Silver-gray metallic | Chrome plating makes parts more corrosion-resistant, easier to maintain, or just looks better. |

Injection Molding FAQ

Our mold-making process has six steps:

1. Determine requirements and arrange production.

2. Provide a free, detailed production DFM report for further analysis.

3. Put the mold into production and provide the Tooling Schedule form for the whole cycle.

4. Provide a free sample to test. Put the mold into production and provide the Tooling Schedule form for the whole cycle.

Step 5: Mass production: Client confirms the samples are qualified, then proceed with the subsequent production.

Step 6: Mold saving: Production is completed and delivered after quality inspection. Mold will be cleaned and stored for the next round of parts production.

Tolerances are important in injection molding. Without proper control, assembly issues can arise. At RapidDirect, we follow the ISO 2068-c standard for molding tolerances, but can accommodate tighter specifications if needed.

No minimum order. Larger quantities = lower prices.

Once an order is placed, it takes about 35 days to make the mold and another 3-5 days to make the parts.

Our services cost more if they're bigger, more complex, made of different materials, or need extra processing. We'll give you a quote after looking at these factors.

LRD prototyping offers rapid prototyping services. This lets you test and verify your design before production.

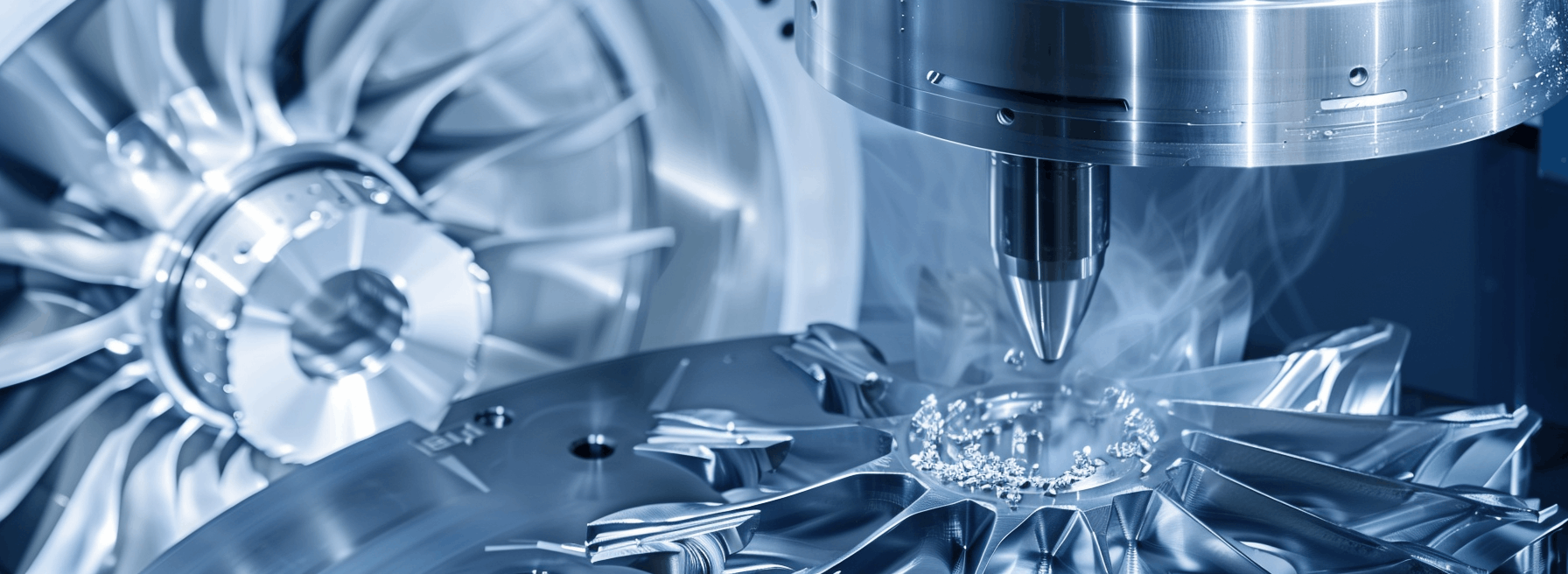

Rapid Injection Moulding Overview

Injection Molding vs. Vacuum Casting

Vacuum (urethane) casting offers a lower front-end cost with a higher unit price, while injection molding demands a higher front-end cost, but a significantly lower unit price. With higher volume production runs, the return on investment (ROI) will be lower with vacuum casting than with injection molding.

Rapid injection molding is used to produce low-volume (up to 100,000) quality production parts and prototypes from real materials. This process is used for prototyping, bridging, and low-volume production run parts in less time and at a reduced cost than full production molding.

Advantages of injection molding include:

Cost-effective

Highly efficient and reliable

Real production-grade materials

Flexibility (in materials and colors)

High-quality parts

Rapid prototyping and on-demand production for a variety of industries.

01.

Automotive

02.

MedicalDevices

02.MedicalDevices

On-demand manufacturing. Rapid prototyping to mass production of medical products.

Learn more 03.

Robotics

03. Robotics

Maximize efficiency by ensuring precise, consistent, and rapid part quality.

Learn more 04.

Communication

04.Communication

Empower your team to innovate more quickly, thereby maximizing their performance.

Learn more 05.

Aerospace

05. Aerospace

Our goal is to provide efficient production and faster design-to-delivery times.

Learn more 06.

Electronics

Related Article

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

How Much Does CNC Machining Cost?

June 20, 2024

No Comments

How does CNC programming work?

June 5, 2024

No Comments

What are the requirements for machining precision parts?

May 30, 2024

No Comments

Previous image

Next image